Date: Wednesday, October 5

Time: 11:00 a.m. – 12:00 p.m. ET

Location: Seminar in-person only; 12-0168

>>Register.

The flexible electronics industry has generally relied on experiences from textiles, electronics, semiconductor, and other industries. As new flexible hybrid electronic products emerge from research to scale, in terms of assuring reliability, the inhibiting factor is to better determine the combination of electronics functionality with flexible substrates (e.g., textile or plastics), whereas previously, any reliability emphasis was on measuring the material’s physical limitations.

New reliability solutions are required to solve three major failure criteria emerging from the development of new materials and new processes. These are:

- Ensure the integrity of new materials and electronics while in continuous use;

- Detect micro-strain fractures of new materials, e.g., delamination and deformation;

- Perform such continuous motion assessments in multi-climate conditions focused on actual human movement.

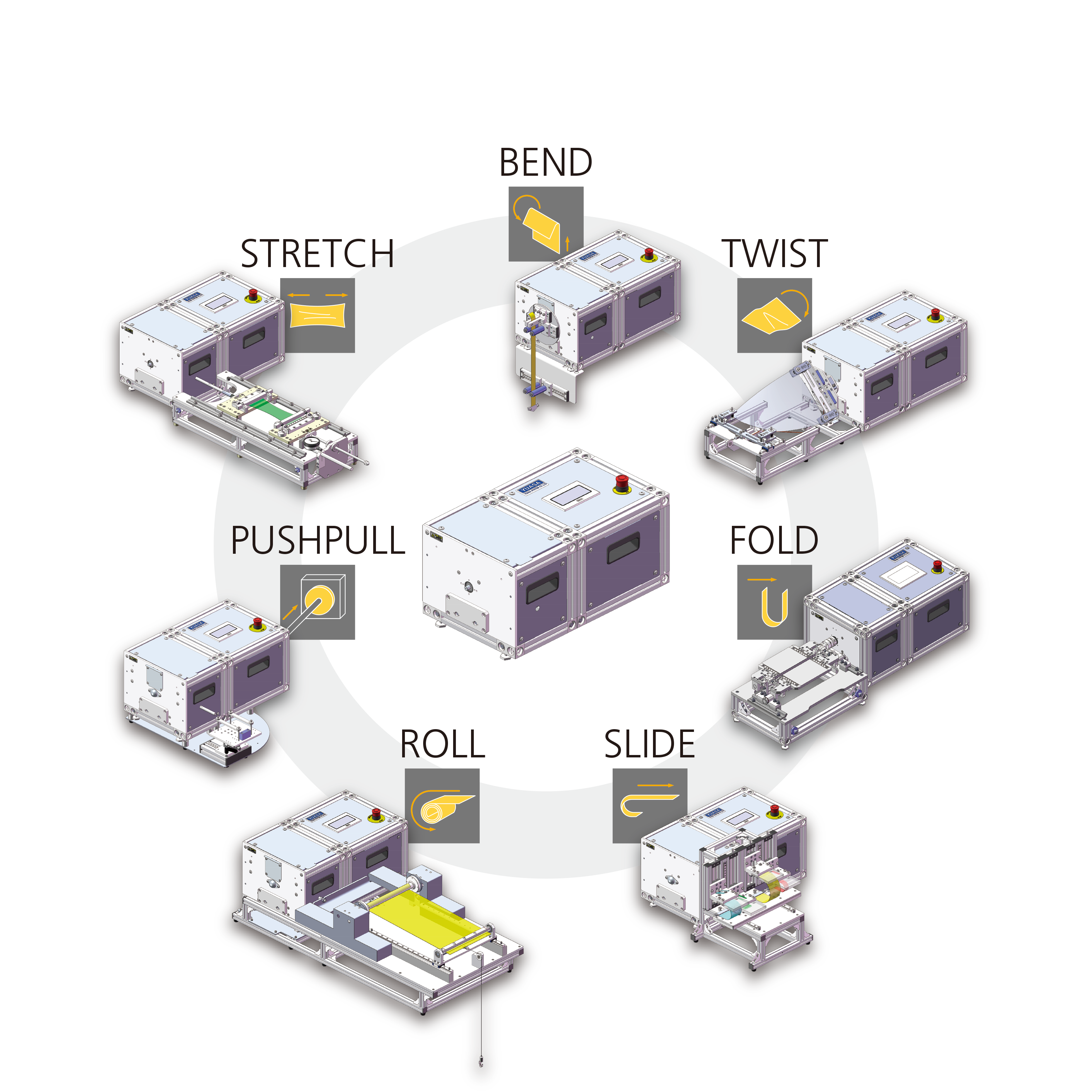

Bayflex Solutions makes available configurable systems that enable continuous tests with accurate, reproducible mechanical tools, add data harvesting, ingest various images, and allow third-party device integration. This provides a common data framework as well as the ability to develop analytics in hostile conditions to form a repeatable knowledge base, support industrial standards, and improve human resources planning. As a result, scientists and engineers are gaining a broader experience of new materials and manufacturing processes faster to materialize the flexible electronics transformation.

Specific case studies and solutions will be demonstrated and made available for a limited time at MIT.